Approved Document K, 2013 edition - Requirement K4: Protection against impact with glazing

Protection against impact with glazing K4. Glazing, with which people are likely to come into contact whilst moving in or about the building shall:

- if broken on impact, break in a way which is unlikely to cause injury; or

- resist impact without breaking; or

- be shielded or protected from impact.

Performance

In the Secretary of State’s view, you can meet requirement K4 if you adopt, in critical locations, one of the following approaches.

- Measures to limit the risk of cutting and piercing injuries by the use of glazing that is reasonably safe, such that, if breakage did occur, any particles would be relatively harmless.

- Use of glazing sufficiently robust to ensure that the risk of breakage is low.

- Steps are taken to limit the risk of contact with the glazing.

Impacts with glazing, particularly glazing in doors and door side panels, and at low level in walls and partitions, can result in cutting and piercing injuries. For doors and door side panels, the risk is greatest for glazing between floor and shoulder level when near to door handles and push plates, especially when normal building movement causes doors to stick.

Hands, wrists and arms are particularly vulnerable. An initial impact at between waist and shoulder levels can be followed by a fall through the glazing, resulting in additional injury to the face and body.

In walls and partitions, away from doors, the risks relate predominantly to glazing at low level. At that level, children are especially vulnerable.

Section 5: Protection against impact with glazing

Glazing in critical locations for all buildings

5.1 Diagram 5.1 shows critical locations in terms of safety, critical glazing locations in internal and external walls.

5.2 In critical locations, comply with one of the following.

- Ensure that glazing, if it breaks, will break safely (see paragraphs 5.3 and 5.4).

- Choose glazing that is one of the following:

- robust (see paragraph 5.5)

- in small panes (see paragraphs 5.6 and 5.7)

- Permanently protect glazing (see paragraph 5.8)

Safe breakage

- 5.3 Safe breakage is defined in BS EN 12600 section 4 and BS 6206 clause 5.3. In an impact test, a breakage is safe if it creates one of the following. a. A small clear opening only, with detached particles no larger than the specified maximum size. b. Disintegration, with small detached particles. c. Broken glazing in separate pieces that are not sharp or pointed.

- 5.4 A glazing material would be suitable for a critical location if it complies with one of the following. a. It satisfies the requirements of Class 3 of BS EN 12600 or Class C of BS 6206. b. It is installed in a door or in a door side panel and has a pane width exceeding 900mm and it satisfies the requirements of Class 2 of BS EN 12600 or Class B of BS 6206.

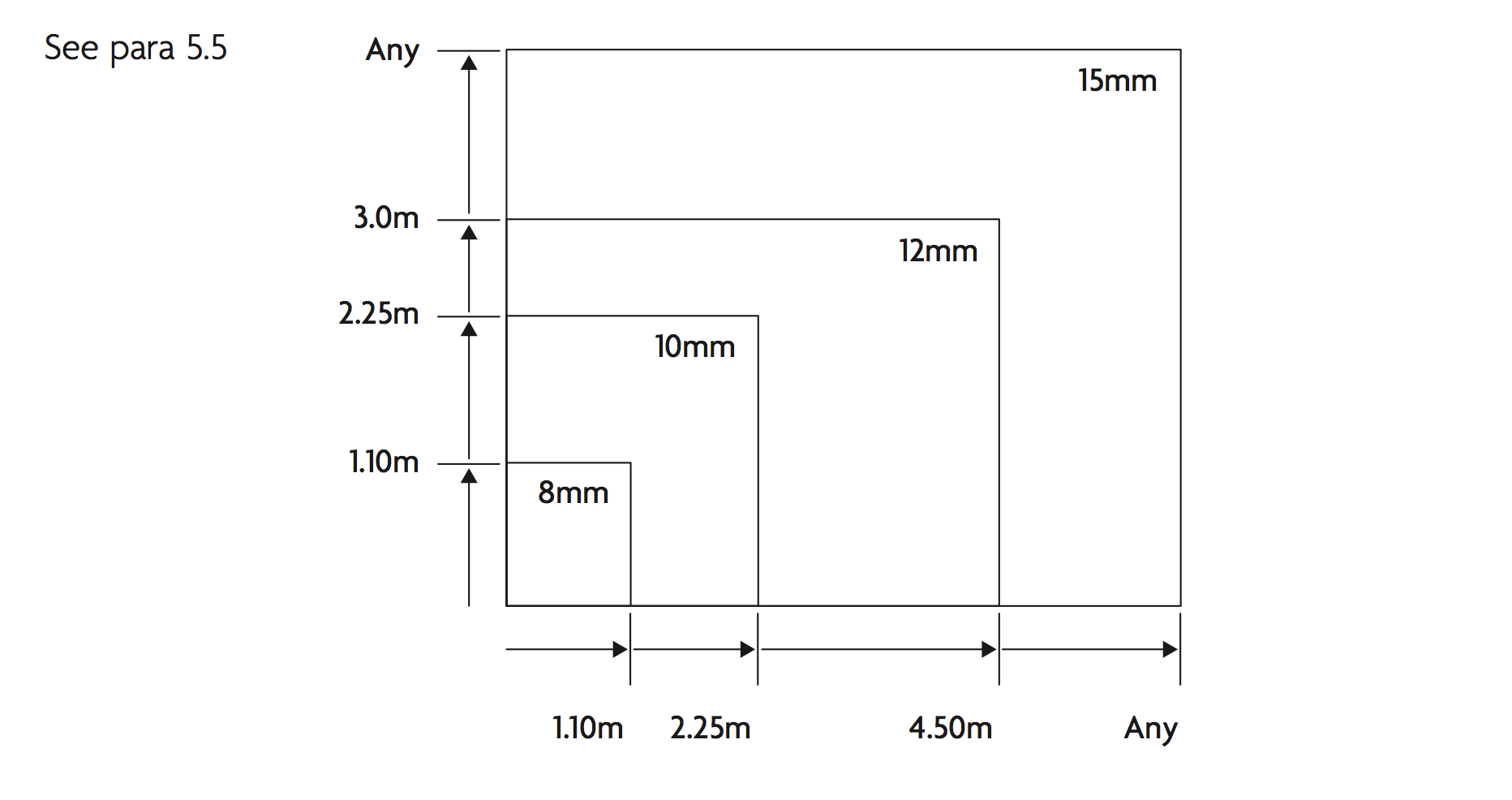

Robustness

5.5 Some glazing materials such as annealed glass gain strength through thickness; others such as polycarbonates or glass blocks are inherently strong.

The maximum dimensions for annealed glass of different thicknesses for use in large areas forming fronts to shops, showrooms, offices, factories and public buildings with four edges supported are shown in Diagram 5.2 (see also paragraph 7.1).

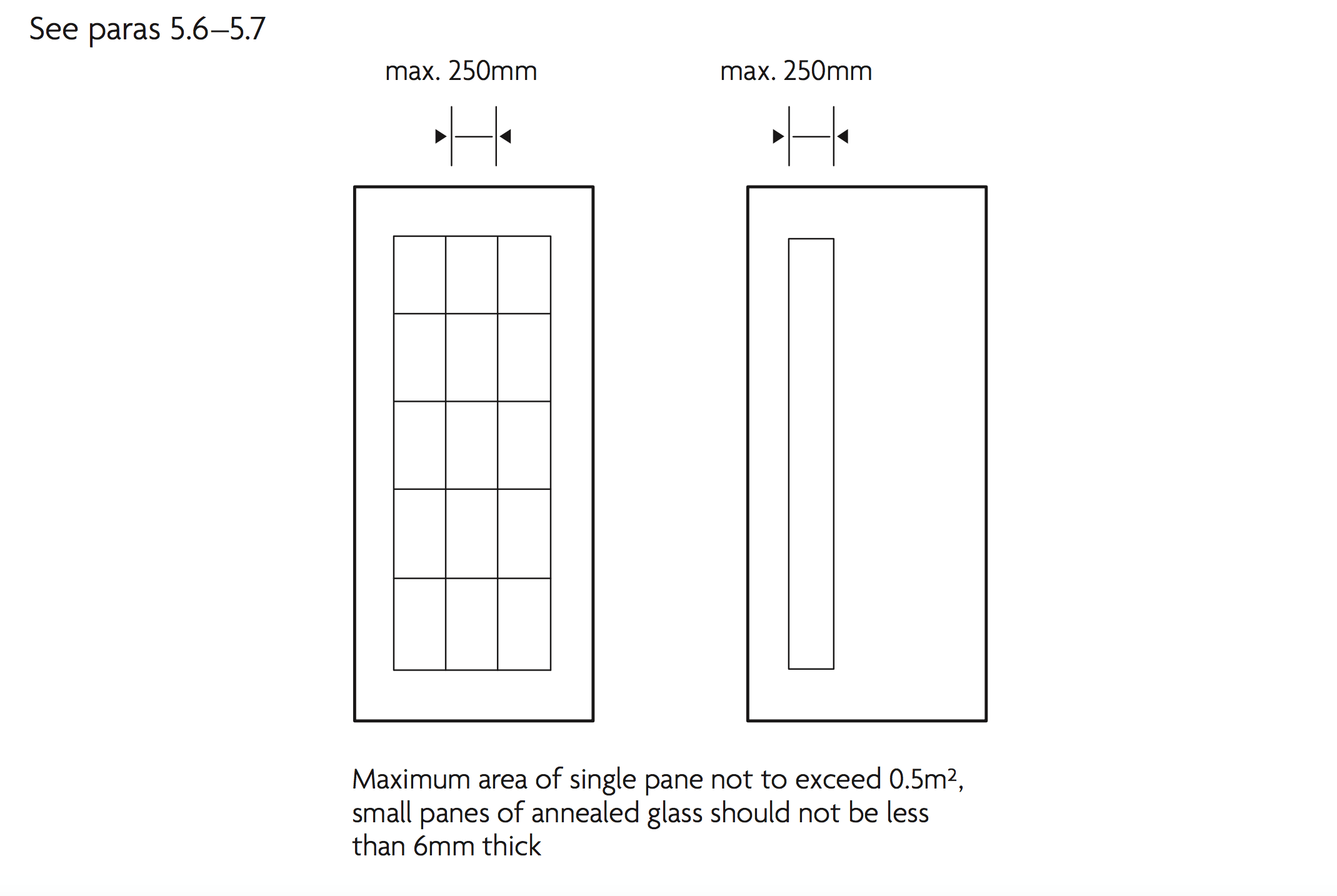

Glazing in small panes

5.6 In the context of this approved document, a ‘small pane’ is an isolated pane or one of a number of panes held in glazing bars, traditional leaded lights or copper lights (see Diagram 5.3)

5.7 Small panes should be provided in accordance with all of the following.

- In a small annealed glass pane, use glass with a minimum 6mm nominal thickness except in the situation described in b.

- In traditional leaded or copper lights, when fire resistance is not important, you may use 4mm glass.

- Use the dimensions and areas shown in Diagram 5.3.

Requirement K5.2: Manifestation of glazing

Manifestation of glazing

K5.2 Transparent glazing, with which people are likely to come into contact while moving in or about the building, shall incorporate features which make it apparent.

Performance

In the Secretary of State’s view, you can meet requirement K5.2 by including, in critical locations, permanent means of indicating the presence of large uninterrupted areas of transparent glazing.

Section 7: Manifestation of glazing

Critical Locations

7.1 Critical locations (see paragraph 5.1) include large uninterrupted areas of transparent glazing which form, or are part of, the internal or external walls and doors of shops, showrooms, offices, factories, public or other non-domestic buildings.

7.2 The risk of collision is greatest when two parts of the building, or the building and its immediate surroundings, are at the same level but separated by transparent glazing and people may think they can walk from one part to the other.

Permanent methods to indicate glazing, and alternative methods

7.3 People moving in or around a building might not see glazing in critical locations and can collide with it. To avoid this one of the following should be adopted.

- Use permanent manifestation to make glazing apparent (see paragraph 7.4).

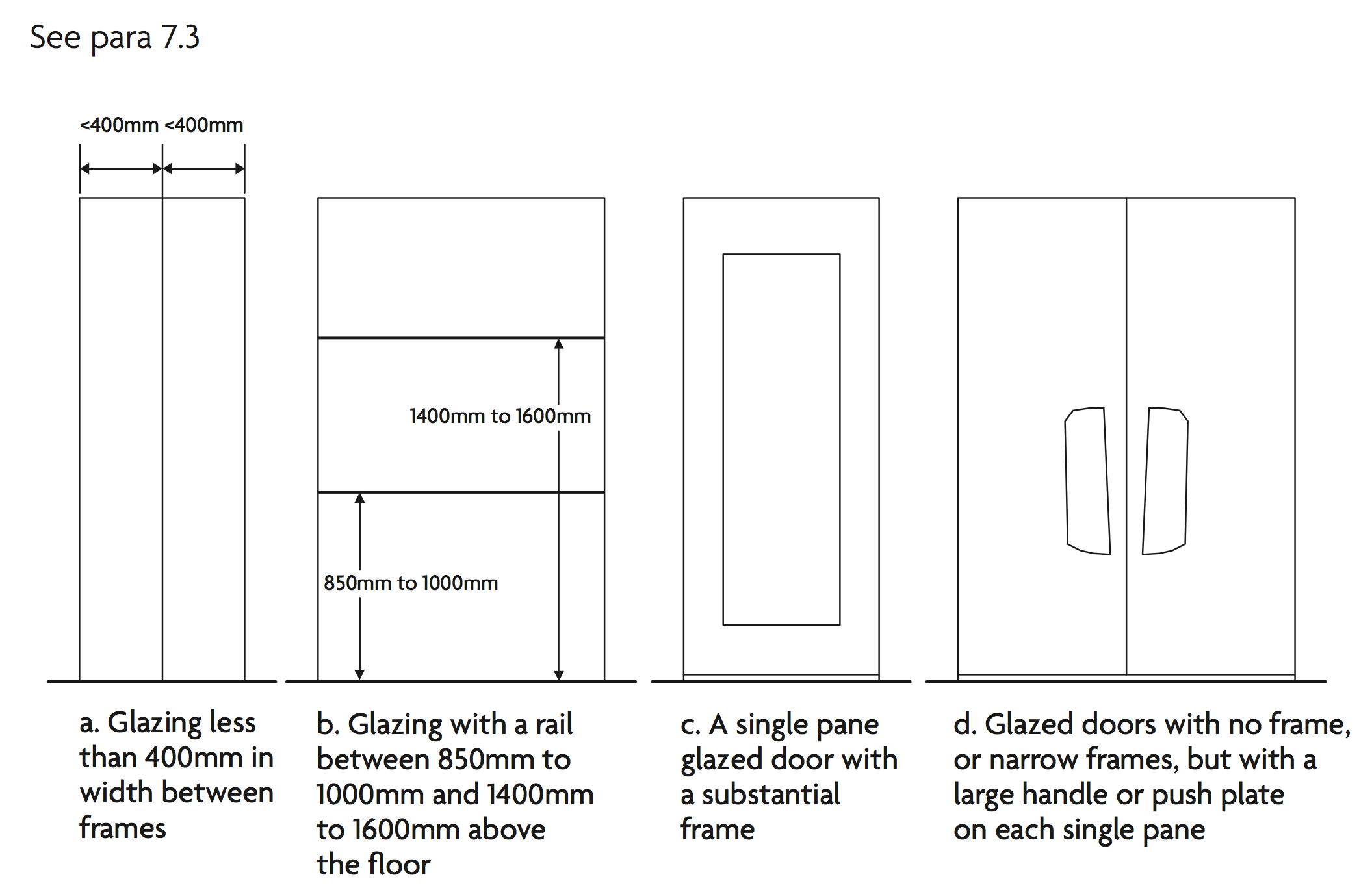

- Use alternative indications of glazing, such as mullions, transoms, door framing or large pull or push handles (see Diagram 7.1).

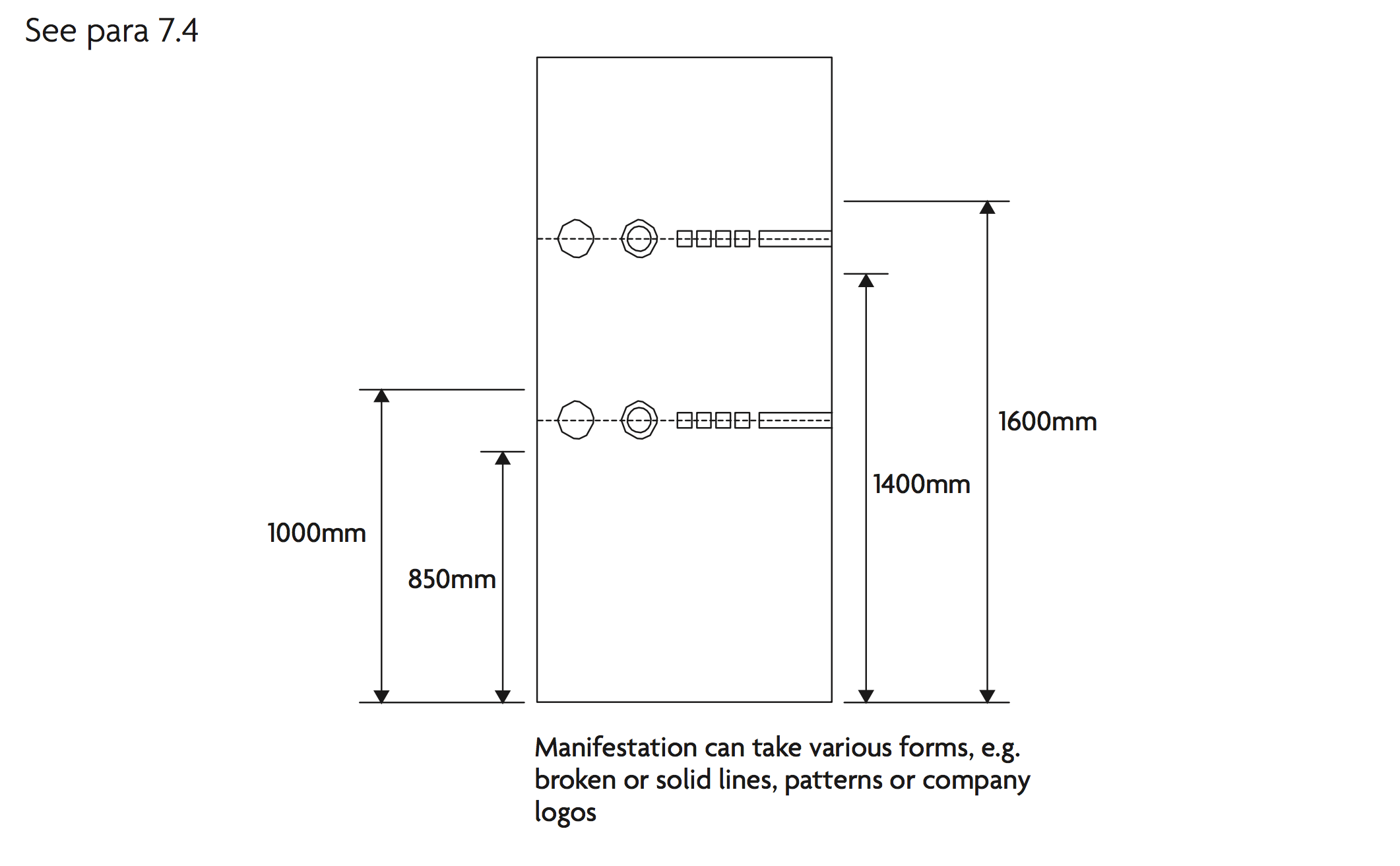

7.4 Provide glass doors and glazed screens (including glazed screens alongside a corridor) with all of the following.

- Manifestation at two levels, as shown in Diagram 7.2.

- Manifestation that will contrast visually with the background seen through the glass, both from inside and outside, in all lighting conditions

- Manifestation in the form of a logo or sign, a minimum of 150mm high (repeated if on a glazed screen), or a decorative feature such as broken lines or continuous bands, a minimum of 50mm high.

- Where glazed doors are beside or part of a glazed screen, they are clearly marked with a high- contrast strip at the top and on both sides.

- Where glass doors may be held open, they are protected with guarding to prevent people colliding with the leading edge.

Diagram 7.1 Examples of door-height glazing not warranting manifestation

Diagram 7.1 Examples of door-height glazing not warranting manifestation

7.2 Height of manifestation for glass doors and glazed screens

7.2 Height of manifestation for glass doors and glazed screens

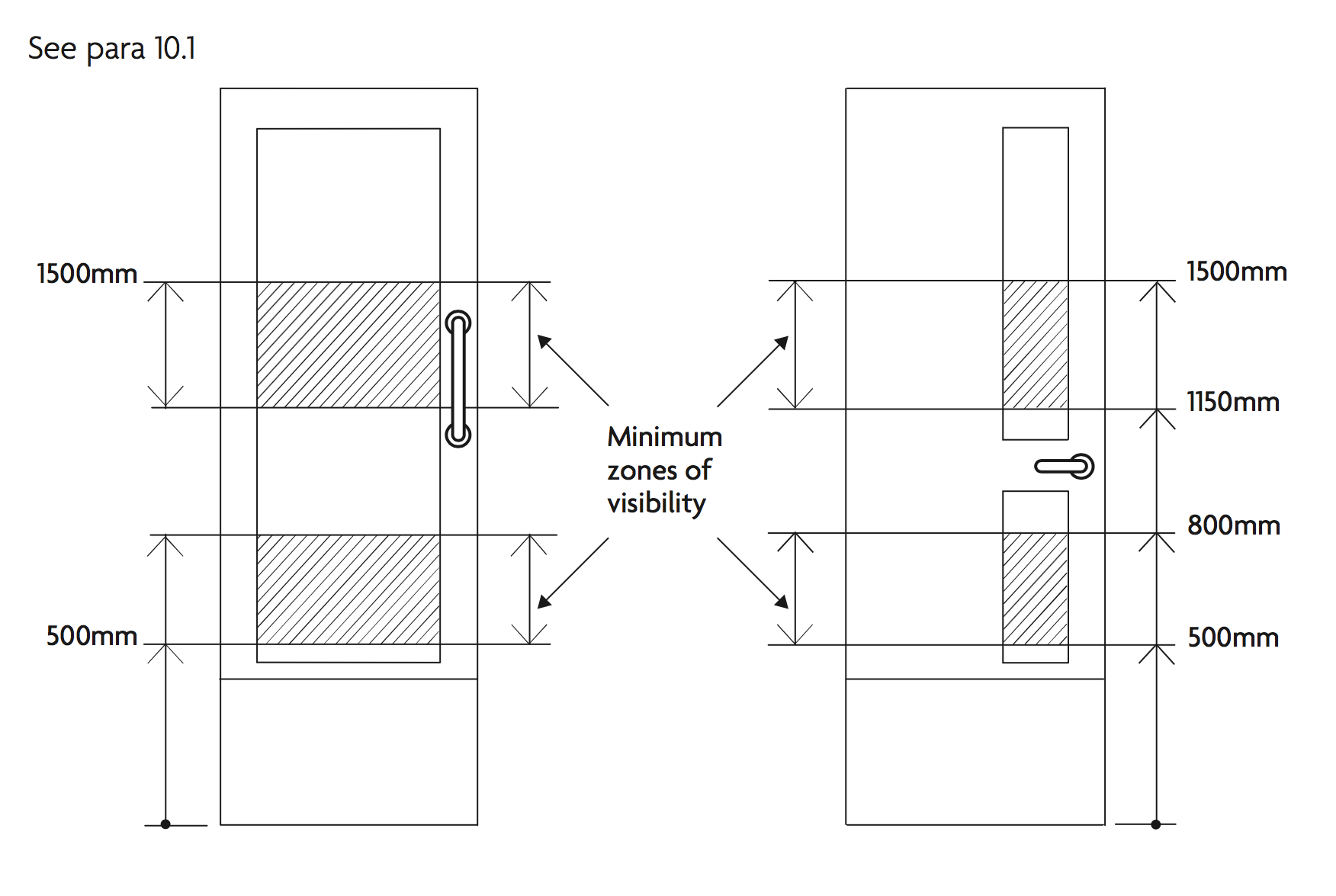

Diagram: Visibility requirements for doors.

Diagram: Visibility requirements for doors.

Glass Manifestation is the ideal solution!

Glass Manifestation are a fast, cost effective route to compliance with glass manifestation regulations which can be installed with minimum disruption to a building’s occupants.

Glass Manifestation satisfies the requirement to make glass more apparent and improve safety. They can be in the form of circles, squares, stripes, logos or any bespoke design.

Decorative window film can also be used to meet glass manifestation regulations, and offer a more bespoke solution.

How can Solarshield Window Films help to achieve compliance?

Solarshield Window Films can help you to achieve compliance by;

- Glazing Survey – Solarshield can carry out a glazing survey to ascertain which areas of glazing are non-compliant

- Installing glass manifestation to the areas identified as unsafe and/or non-compliant

Unsure if your glazing is compliant?

Call us today on 0845 130 6232 or